-

Description

File production is a process that Usines Métallurgiques de Vallorbe has been mastering and perfecting for over one hundred years. Although many innovations have enhanced the range of Vallorbe® products over the years, the file remains the main indicator of our expertise.

As global benchmarks, Vallorbe® files are characterised by their unparalleled quality, their point filed right up to the end, grinding capability, precise dimension and high-quality steel.

Be they needle, precision, sharpening or diamond files, our files are the perfect fit.

They have therefore become indispensable in numerous sectors, including industry, forestry, jewellery, watchmaking, blacksmithing and luthiery.

-

Choosing the right file

Main dimensions of our files

L = length

A = width or diameter

B = thickness

The length is measured in millimetres or in inches, depending on the model. This measurement may or may not include the tang, depending on the type of file.

A and B are measured in millimetres and are purely indicative. For items LA, LE, LP, LH, LR, LO and LQ, these dimensions are always calculated on the largest uncut section. For items RA, LAC, LEC, DA, DR and DH, the dimensions are measured on the largest cut section and are average values following the number of the cut.

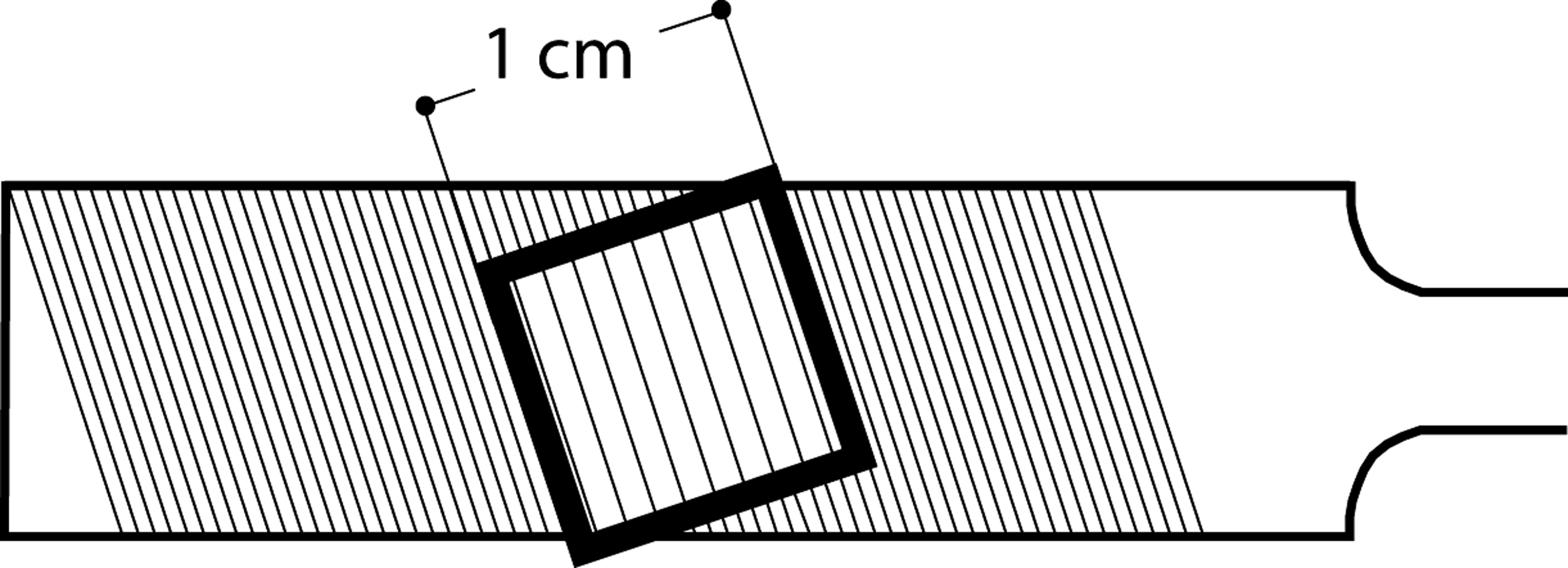

The number of teeth on our files is counted perpendicular to the cut of the files.

The dimension and the cut of the files are determined by the material on which you wish to work.

Soft materials such as wood, plaster or horn and synthetic materials require coarse files or rasps.

If you are working on non-ferrous metals such as aluminium, brass or copper, milled or coarse files are recommended.

For ferrous metals such as hardened steels or titanium alloys, you will need a fine file, or a Valtitan®-coated or diamond file.

The profile being filed dictates the file profile you will need.

Finally, the dimension of the file you will need is determined by the size of the workpiece from which you wish to remove the material.

Documents

-

Scale of cuts

To determinate number of teeth (Z/cm)

The number of teeth (Z/cm) is obtained by counting perpendicularly to the cut.

In the following table the figures correspond to the number of teeth per cm, for a given length and type of file.

For example : a file 6" in cut 2 = shows 31 Z/cm.

Documents

-

Finishing ranges

The Glardon® tools are the perfect solution 100% Swiss Made which combines quality and performance for demanding experts.

Vallorbe® proposes an intermediate Swiss Made range with a price / performance solution appropriated for some markets. These tools have excellent cutting performance and are ideal for many applications, particularly in industry.

A Vallorbe® selection for entry level markets. These tools offer maximum performance for an attractive price.